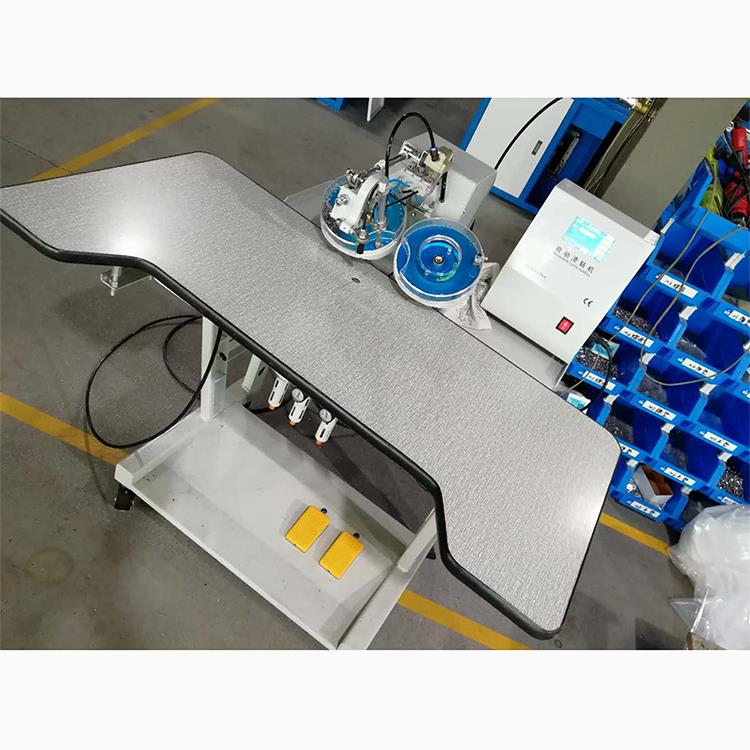

Rhinestone hot fix machine has the characteristics of automatic ball suction, automatic setting rhinestone, etc., when the diamond moves to the product to be processed, ultrasonic wave automatically produces, forms micro-amplitude and high-frequency vibration on the water drill, and instantly converts into heat, melts the material to be processed, and finally makes the water drill permanently paste or embedded in the surface of the processed product. This kind of equipment makes processing speed get certain rise, with a few manpower investment can realize mass production, paste firm and reliable, and can be packaged into finished products in real time. Eliminate the negative effects of glue use. The machine mainly has portable ultrasonic spot drilling machine (commonly known as portable ultrasonic spot welding machine, portable ultrasonic welding machine). In addition, at present, there is also a hot - press point - drilling machine that directly USES heat conduction components for point - drilling. What introduce here basically is a kind of principle that USES supersonic wave, make water drill adheres in cloth, leather, plastic, the equipment of surface of force of force of pressure gram, by palm model power transducer, supersonic wave generator and electromagnetism type air compressor form.